Enquire today for a custom build vehicle tailored to your needs.

Electric vehicle of up to 18 tonnes.

The RT runs on electricity. But that’s not its only revolutionary feature. The electric drive is just the starting point of a long series of special design features that bring decisive advantages: for the operational procedure, the operations management system, the operational environment – and above all for the emergency crews.

The RT was not just designed to be state of the art in terms of technology. The goal was to meet the future requirements of fire services already today. This makes the RT not just a milestone for Rosenbauer, but also for the entire firefighting an emergency response industry.

The RT has a charging capacity of up to 150 kW, which means that the built-in batteries can be recharged in no time at all. This means that purely electric and therefore emission-free short-range operation!

The batteries of the RT can be charged with three-phase alternating current (AC: 11 kW or 22 kW) from a high-voltage industrial socket, without the need for a special adapter. The high-performance high-voltage batteries also provide sufficient output for external consumers. Several external devices with a combined power consumption of up to 18 kW can be operated simultaneously via the power outlet.

When the vehicle comes to a standstill, the engine is automatically deactivated. The lighting and equipment are powered directly by the batteries. This greatly reduces the noise level at the scene of the emergency, making it easier for the crew to work, reducing stress, and benefiting nearby residents. The RT’s electric drive is not only powerful, but also emission-free. The batteries ensure that no fuel is combusted while driving.

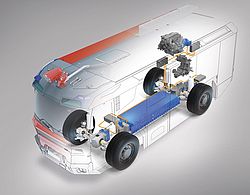

In the RT product line, the combustion engine has not merely been replaced by an electric one. Instead, a completely new drive concept is revolutionising the architecture of the tank firefighting vehicle, with numerous positive effects. The drive concept enables a lower centre of gravity and a more balanced axle load distribution. This gives unprecedented cornering stability and thus reduces the risk of accidents.

Manoeuvrability is of the utmost importance for municipal emergency vehicles, especially in urban areas. With the RT, Rosenbauer engineers have pushed the limits of what is possible. No other vehicle with comparable extinguishing and transport capacities has such compact dimensions or an equally small turning radius.

The revolutionary vehicle concept of the RT offers both ergonomic and tactical advantages – for less physical strain on the emergency crews and for greater operational success.

The position of the pump room has been moved forward in the RT, creating additional equipment compartment with a low loading edge in the rear of the vehicle. This results in even more storage space at a low height, with heavy equipment needing to be lifted less often.

Especially in terms of firefighting equipment, each RT model can be individually tailored to the intended operational scope: The volumes of the water tanks range from 1,000 L to 3,000 L, those of the foam tanks from 50 L to 400 L. Both normal and combined normal/high pressure pumps are available. All available pumps can be operated either purely by means of the battery-powered electric motor or, especially in the case of longer operations, using the diesel-powered Energy Backup System.

Both normal and combined normal/high pressure pumps are available for the RT. They can also be fully operated in battery-powered mode.

| N/NH25 | N/NH35 | |

| Flow at normal pressure (10 bar / 150 PSI) | 2,500 L/min | 3,500 L/min |

| Flow at high pressure (40 bar / 600 PSI) | 400 L/min | 400 L/min |

| with shut-off flap and suction head, suction height 1.5 m Maximum power depending on suction power |

The cockpit and crew cabin were also redesigned to ensure the greatest possible interaction between the crew members.

A completely new type of crew cabin with a rugged design ensures a high level of passive safety in the event of an accident.

With a distance of just 260 mm between the road surface and the cabin floor in operational mode, it has never been easier to enter or exit a tank firefighting vehicle. The RT eliminates the need for fold-down steps, ladders and stairs. This reduces the risk of injury and long-term stresses on the emergency personnel.

With the RT, Rosenbauer is breaking completely new ground in order to make the vehicle’s controls and firefighting equipment even safer and easier to use as well as to improve the coordination of the emergency crews.

The RT is at the core of an own communication system. It consists of a telematics module with a Wi-Fi hotspot integrated on the vehicle. This can be used to transmit live data from the vehicle via RDS Connected Fleet, which supports equipment maintenance/the fleet manager. It can also be used to connect to an RDS Connected Command tablet for linking to the command centre, and for remote operation of vehicle functions. Additionally, the integration of drones for aerial image-based analysis of the operation is possible.

The 17” display is located centrally in the cab. This is used to operate the whole vehicle, including the classic chassis functions such as air-conditioner or differential locks. Bodywork functions such as emergency warning lights, road traffic control devices as well as the pump unit and foam proportioning systems can also be operated from this display.

When used in conjunction with the RDS Connected Command tablet, the central display can also be viewed as a presentation screen for operational planning of the crew. For example, fire safety plans can be shared as the crew approaches the scene.

Moreover, in addition to conventional switches, customisable operational buttons ensure maximum simplification of recurring scenarios, such as securing the operational site.

Drivers of Rosenbauer’s RT vehicles are supported by a large number of assistance systems that help avoid accidents in difficult situations.

A clear view around the fire truck is a basic requirement for successful and safe operation. The integrated high-performance LED strips with their powerful luminosity ensure shadowless illumination of the operating environment and, in many scenarios, even make a lightmast superfluous.

In addition, the cornering lights make it easier to see pedestrians when driving. This increases the protection of pedestrians and actively helps to reduce the risk of accidents on the way to the scene of the emergency.

Enquire today for a custom build vehicle tailored to your needs.