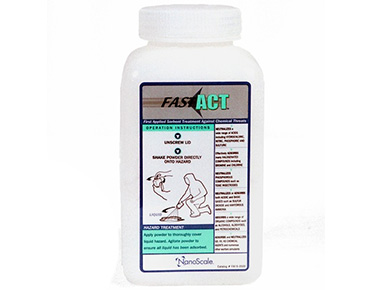

FAST-ACT is a non-toxic high-performance chemical neutraliser powder designed to effectively neutralise a wide range of toxic chemicals with the added capability to destroy chemical warfare agents.

FAST-ACT is a combination of common metal oxides (MgO + TiO2) with a unique morphology. It has nanomaterial properties with a final particle size of nearly 5μm. The production process creates an altered, non-toxic molecular structure with large increase in porosity and surface area.

FAST-ACT chemical neutraliser is non-flammable, non-corrosive, and significantly reduces both liquid and vapour hazards. Since the dry powder neutralises threats upon contact, on-site incident management and clean up times are reduced.

FAST-ACT chemical neutraliser works quickly to significantly reduce hazards associated with common industrial chemicals including: acids, acidic/caustic gases, organic compounds, phosphorus and sulphur compounds, and many industrial solvents. By the nature of its chemistry, hazardous substances are chemically bound to the surface of the powder, minimising off-gassing.

FAST-ACT can be safely applied to any liquid spill or vapour-release, enabling emergency responders to use just one solution when faced with a wide variety of known or unknown chemical hazards.

- Use FAST-ACT chemical neutraliser on acids, halogenated compounds, phosphorous compounds, acidic and caustic gasses as well as organic compounds.

- Formulation of safe earth minerals in a dry powder form.

- Neutralises both liquids and vapours.

- Supplied in a handy shaker bottle.

- No special training required.

- Shaker bottle also includes BONUS wall unit

-

Code Description Size FA15-0500WALL FAST-ACT chemical neutraliser 500g shaker bottle 500g shaker bottle also includes bonus wall holder.

FAST-ACT is a combination of common metal oxides (MgO + TiO2) with a unique morphology. It has nanomaterial properties with a final particle size of nearly 5μm. The production process creates an altered, non-toxic molecular structure with large increase in porosity and surface area.