A DOP skimming or offloading pump has the ability to pump a wide range of oils, or oil and water mixtures, with a discharge pressure up to 10 bar/147 psi.

The hydraulically driven stainless steel screw rotates inside lightweight aluminium housing. All DOP pumps contain cutting knives to prevent any debris being trapped in the pump and these, combined with a pressure-lubricated screw bearing, greatly increase the reliability of the pump.

The DESMI screw pump was introduced over 25 years ago and has subsequently been developed and improved to become the most widely used viscous oil pump in the oil spill response industry today. Over 2,000 submersible screw DOP pumps have been supplied to more than 100 countries around the world.

DESMI conducted extensive bitumen pumping tests in house. All testing showed that a relatively small amount (3-6%) of water injected into the pump discharge line with an injection flange or camlock forms a thin layer surrounding the column of oil that is travelling through the hose. A system comprising of an injection flange and high-pressure water pump was developed and tested over a two year period. The result means that heavy oils can be pumped further and higher. A steam version is also available for even greater pumping distances with higher viscosities.

- DOP-160

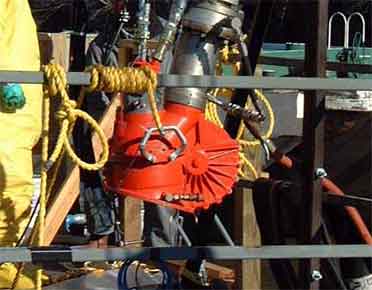

The DOP-160 is a fully submersible vertical screw pump which is able to pump a wide variety of oils and liquids up to 30 m³/hr / 132 US gallons per minute. The DOP-160 offloading pump is a positive displacement pump, making it ideal for oil spill applications. It is capable of handling a wide range of fluids from water to extremely viscous oil, even with some trash content. The screw and casing are fitted with a sturdy cutting knife arrangement that can slice through or crush items such as marine grasses, seaweed, line and plastic. The maximum discharge pressure this pump can generate is 10 bar / 145 psi – far greater than most centrifugal or diaphragm pumps. This high output pressure enables the pump to deliver oil through long lengths of hose.The gentle action of the DOP-160 offloading pump does not emulsify oil and water when pumping. This means that water can be quickly and easily separated from the recovered oil before storage. The pump can be operated at variable speeds from zero to maximum. As it has positive displacement the output is directly proportional to the screw rpm. This allows the operator to accurately set the flow rate to the optimum setting. - DOP-200 Dual

The lightweight and powerful DOP-200 Dual offers the pumping performance of the vertical screw design and incorporates new features to improve versatility and ease of maintenance. The pump can be configured for use in Skimmer Mode with a side (horizontal) discharge. This provides an unobstructed flow into the pump inlet. In Transfer Pump Mode, the discharge can be on the side or end (inline) for maximum operational flexibility.The DOP-200 Dual is available with a variety of systems to make the most of the pumps’ capabilities. The DOP-200 Dual features a single piece cast pump casing and stainless steel wear plates to protect the plate wheel cover. The new housing design allows the pump screw and sealing ring to be withdrawn from the end of the pump for inspection. The discharge branch location can be changed quickly and easily using hand tools.Pressures of up to 13 bar available with the DOP200. - DOP-250 Dual

The lightweight and powerful DESMI DOP-250 Dual can be configured for use in Skimmer Mode with a side (horizontal) discharge. This provides an unobstructed flow into the pump inlet, yet allows the Terminator skimmer to operate in shallow water. In Transfer Pump Mode, the discharge can be on the side or end (in-line) for maximum operational flexibility. The DOP-250 Dual offloading pump is available with a variety of systems to make the most of the pumps’ capabilities. When fitted in the Terminator skimmer it can be easily dismantled and converted for offloading applications.The DOP-250 Dual features a single piece cast pump casing and stainless steel wear plates to protect the plate wheel cover. The new housing design allows the pump screw and sealing ring to be withdrawn from the end of the pump for inspection. The discharge branch location can be changed quickly and easily using hand tools.

About DESMI

DESMI designs and manufactures an extensive range of systems to recover oil and chemicals from the marine and inland environment. DESMI products include skimmers, booms, storage tanks, power packs, pumps, dispersant systems, vessels and ancillary items.

DESMI’s extensive range of containment booms and oil skimmers supports their oil spill response solutions which are highly trusted in the industry. Whether the requirement is for offshore or shoreline areas; the arctic or equatorial environment, DESMI delivers proven solutions for all spill conditions and offers outstanding life-cycle costs.