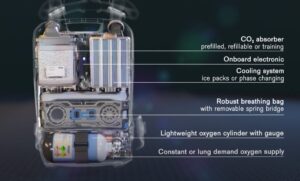

Specially designed for longer durations: The Dräger BG ProAir is a positive pressure closed circuit breathing apparatus that combines uncompromising safety with the highest level of breathing and carrying comfort. Easier to carry, easier to breathe – giving you more time to get the job done and return safely.

Perfectly made for long-duration deployment

Optionally, the oxygen can be dosed according to your work rate thus providing you with an even longer duration at low work rates. Because as you respond to rescue tactics, so should your equipment.

USABILITY

The BG ProAir’s weight is evenly distributed due to its smart carrying system making it easier and more comfortable to wear during longer missions. Additional safety features on the housing include: highly visible reflectors and a buddy light system which helps your team members to see you and know the status of your apparatus.

Easier to breathe and easier to use

The cooling options include a state-of-the-art regeneration material as well as a simplified ice system to reduce the temperature of the inhaled air without the need to either open the breathing loop or remove components while in use. The larger surface area of the cooling elements provides comfortable breathing air for a longer period of time. To further improve the breathing comfort, key components in the breathing loop have been innovatively redesigned to significantly reduce breathing resistance.

Blue colour-coded touchpoints throughout the breathing apparatus make the handling more intuitive and therefore reduce your training efforts and equipment downtime. The same system components from the well-known PSS BG 4 are available: the FPS 7000 full-face mask, in-mask communication, test equipment, oxygen booster pump, and Drägersorb.

CONNECTIVITY

Reading vital information, such as cylinder pressure, in-use warnings and time to whistle, is now simpler and clearer than before. With its high contrast, full-colour display, your data is plainly visible even in the most difficult environments such as darkness, bright sunlight or smoke. An integrated Bluetooth® module provides a short range connection to work with external devices such as gas detectors as well as a PC connection to download data and perform configuration. The BG ProAir’s integrated data telemetry and RFID assists you in multiple scenarios such as entry control management and absorber status tracking. In addition to time calculations such as time to whistle, we have also integrated recognised features like PASS, ADSU and temperature readings.

* Bluetooth® is a registered trademark of Bluetooth SIG, Inc.

SAFETY+

To reliably protect you against toxic ambient gases, the Dräger BG ProAir continually provides you with positive pressure even when your breathing rate increases in the breathing circuit. It is further enhanced by smart onboard electronics, which include a low-pressure sensor. The integrated low pressure sensor warns when there is a lack of oxygen to ensure safe breathing. The sensor also provides a low pressure leak test of the breathing system.

Going the extra mile

With its fully sealed housing, the BG ProAir has been approved to the highest standards for heat, flame, and chemical resistance providing you with safe breathing air according to international standards. For additional safety, it also comes with an optional buddy system, which enables the user to safely share oxygen with those in need during rescue situations.

SERVICEABILITY

We understand that your time is of the essence. For this reason, plug’n’play connectors make the BG ProAir easy to assemble and disassemble, while spending less time on training. No tools are required for maintenance and service frequency is conveniently reduced, such as only replacing the reducer every 10 years.

Quick to clean and smart to cool

We have simplified every cleaning aspect of the BG ProAir: It’s completely machine washable and you have fewer parts to clean and disassemble. The waterproof harness can be effortlessly disassembled from the housing, making it even easier to clean and quick to dry. We have also re-engineered the cooling logistics making it more straightforward for you to reuse the ice packs and regeneration material. The new ice pack system simplifies the freezing process without the need to handle water; while the regeneration material does not require ice and can be stored in the apparatus at temperatures below 25 °C / 77 °F.