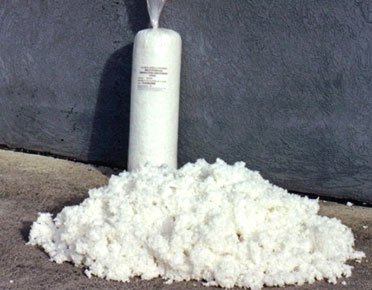

Oil absorbent particulate is used indoors or outdoors wherever oils and fuels are stored, handled, dispensed and spilled – use on land, in the rain or on water. Absorbent particulate features a large surface area and can be sprinkled onto and around the spill with precision.

Oil and fuel absorbents are made from meltblown polypropylene and are colour-coded white for easy identification. These absorbents are able to absorb up to 20 times their own weight in oil and have a fast-wicking action to clean up spills quickly. Oil and fuel absorbents are hydrophobic, which means they repel water. This makes them ideal for cleaning up oil and fuel spills in wet environments, including ponds, sumps, drains, lakes, rivers, creeks or in the rain.

- Oil absorbent particulate is ideal for maintenance workshops, paint and panel shops, parking and laydown areas, vehicle repair shops, re-fuelling facilities, service stations, ports and marinas, wash and lube bays.

- Use for oil and fuel spills on concrete, bitumen and hard surfaces.

- Particulate is ideal for placing on and around a spill to solidify and absorb.

- Excellent water repellent characteristics (hydrophobic) – use in the rain or on water to absorb oil and fuel only.

- Made from 100% meltblown polypropylene – able to absorb up to 20 times its own weight in liquid.

- Oil absorbent particulate is an inert, surface-modified polypropylene which does not degrade or chemically react with the absorbed liquid.

- High absorbency to weight ratio = lower transport and disposal costs.

- Non-allergenic, non-hazardous with no dust.

- Fast wicking action allows quick clean up, reduces potential slip hazards and improves safety in the workplace.

- Simple to use without the need for specialised PPE.

- Colour-coded white for easy identification.

| Description | Size | Absorbent capacity per bag | Code |

|---|---|---|---|

| Oil and fuel absorbent particulate | 1.5kg | 30 litres | PTH1.5 |

| Oil and fuel absorbent particulate | 2.5kg | 50 litres | PTH2.5 |

Australian Made

- Absorbent capacity will vary depending on liquid viscosity, specific gravity and temperature.

- Maintenance polypropylene is compatible with, and absorbs most acids and bases.

- The suitability with a specific chemical should be confirmed by referencing the MSDS, a compatibility chart or sample testing. We can provide samples as required.

- Absorbents retain the characteristics of the absorbed liquid. Appropriate PPE should be worn and disposal of used absorbents should be in accordance with local regulations.